Technologies and Innovation

with DAS Instruments since 1977

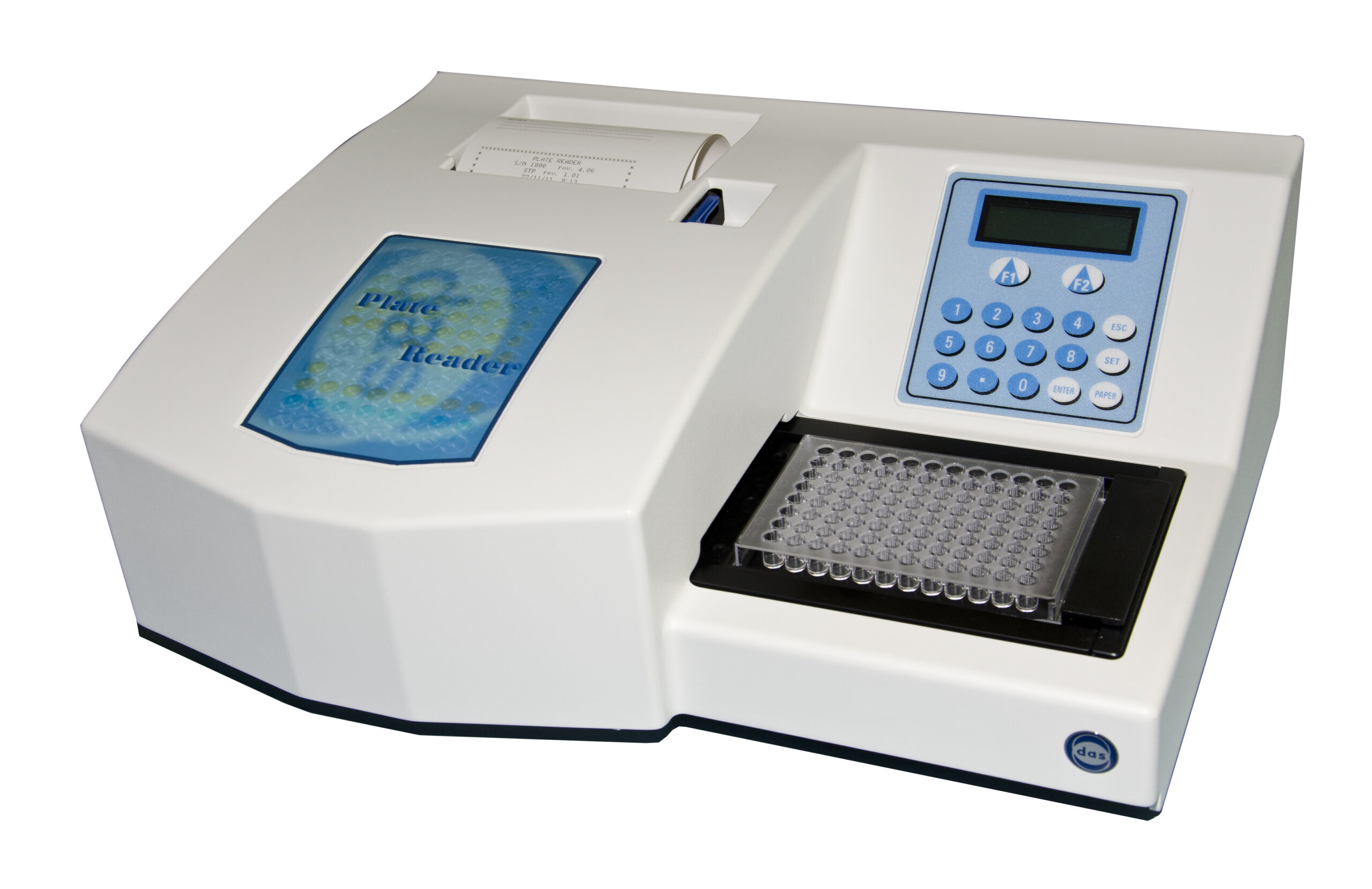

ELISA PLATE READER

PLATE READER is an eight-channel photometer for simultaneous and sequential reading of 96-well microplates. Microplate shaking capacity. Built according to the most advanced technologies, it is of absolute quality and reliability as well as high precision and easy to use. With its powerful software it is able to carry out measurements, processing and related storage.